Understanding the Role of Crusher Screen Manufacturers in Modern Industries

The Importance of Crusher Screens

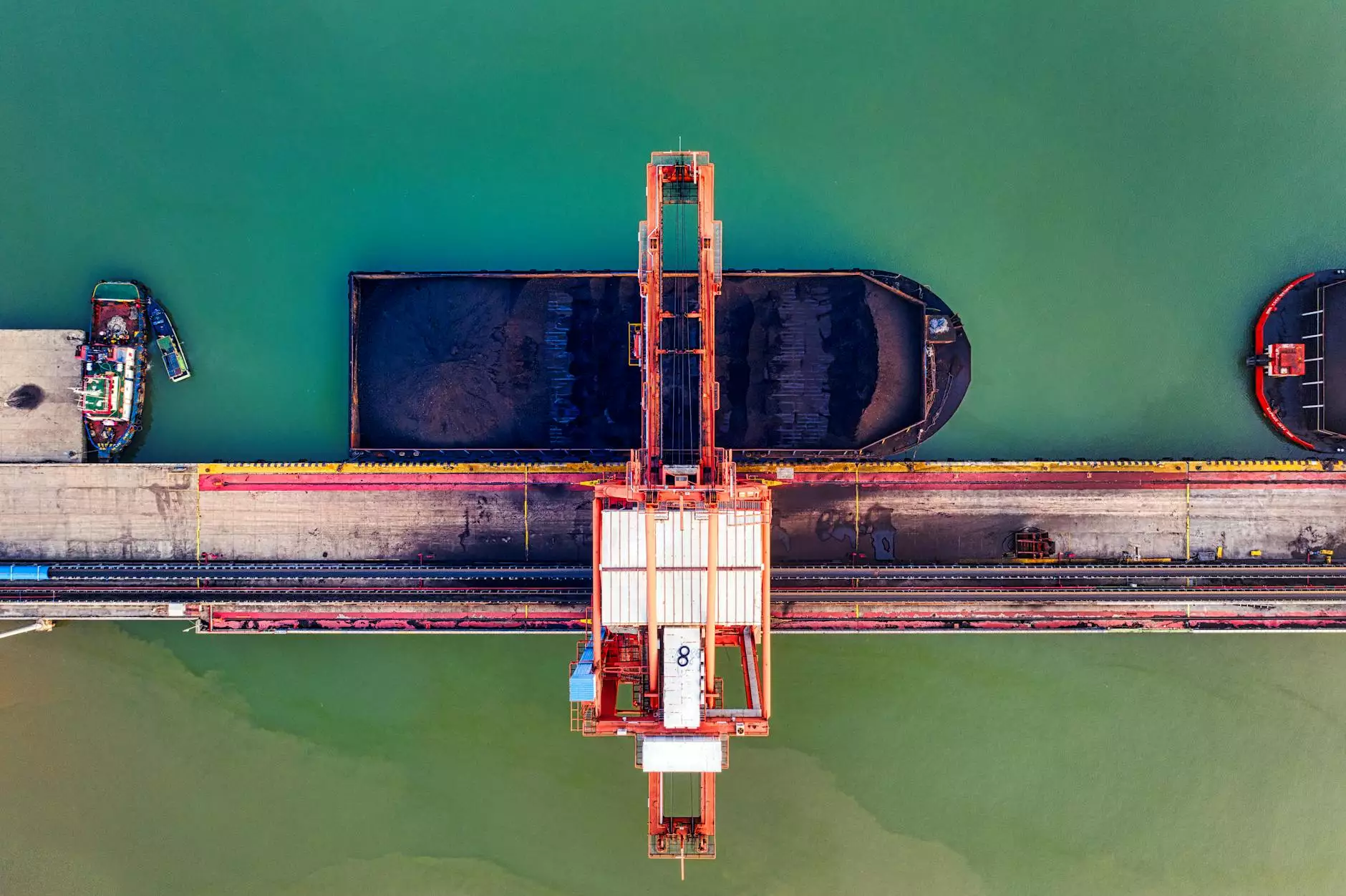

In the realm of construction and mining, the efficiency and productivity of materials handling are critical. Crusher screens play a pivotal role in this process by separating and grading materials, which is essential for various applications. They facilitate the processing of minerals, aggregates, and ores, ensuring that the right sizes of materials are delivered for further processing.

Who Are the Leading Crusher Screen Manufacturers?

The market is filled with numerous crusher screen manufacturers who specialize in designing and producing high-quality screens. Some of the most recognized names in the industry include:

- PolygonMach - Renowned for their innovation and high-performance machinery in the sector.

- Metso - Offers a wide range of screening solutions designed for optimal performance.

- Sandvik - Known for their robust equipment and cutting-edge technology in crushing and screening.

- Terex - Provides a variety of screens tailored to meet different industry requirements.

- KPI-JCI - Specializes in producing screens that enhance productivity for aggregate producers.

Types of Crusher Screens

Different types of crusher screens are designed for various functions. Below are some of the most popular types:

- Vibrating Screens - Utilize vibration to separate materials according to size.

- Horizontal Screens - Effective for dewatering and scalping of materials.

- Inclined Screens - Offer high capacity in screening, often used for mining applications.

- Polymer Screens - Provide durability and flexibility for various applications.

- Wire Mesh Screens - Traditional screens that are widely used due to their effectiveness.

The Technology Behind Crusher Screens

Crusher screen manufacturers are now leveraging advanced technology to enhance the performance of their products. The integration of features such as:

- Self-Cleaning Systems - Help in maintaining optimal performance by reducing blockages.

- Modular Designs - Allow for easy customization and replacement, extending the lifespan of the screens.

- Aerodynamic Shapes - Improve airflow and efficiency during material processing.

- Remote Monitoring - Enables real-time analysis of screen performance, leading to timely interventions.

Applications of Crusher Screens

Crusher screens find applications in a multitude of industries, including:

- Mining - For the classification of ore and minerals.

- Construction - In the production of aggregates for concrete.

- Recycling - For sorting materials like plastic, metal, and glass.

- Waste Management - In processes to separate recyclable materials.

- Agriculture - For the processing of compost and soil amendments.

Advantages of Using High-Quality Crusher Screens

Investing in quality crusher screens from reputable manufacturers such as PolygonMach brings several advantages:

- Increased Efficiency - Optimized designs ensure faster and more effective material screening.

- Durability - High-quality materials lead to longer lifespan and reduced maintenance costs.

- Cost-Effectiveness - Enhanced productivity and reduced downtime translate to lower operational costs.

- Versatility - Capable of handling a variety of materials and adapts to different processing needs.

- Innovative Features - Incorporating technology that improves performance and user experience.

Choosing the Right Crusher Screen Manufacturer

When selecting a crusher screen manufacturer, consider the following factors:

- Reputation - Research customer reviews and case studies to gauge reliability.

- Product Range - Look for manufacturers that offer a comprehensive selection of products.

- Customization - Ensure they can tailor solutions to meet your specific requirements.

- Customer Support - Evaluate the availability of technical support and service options.

- Warranty and Maintenance Services - Good warranties and maintenance help mitigate future risks.

The Future of Crusher Screen Manufacturing

As industries evolve, so do the techniques and technologies around crusher screens. The future is likely to bring:

- Smart Technology - Increased integration of IoT devices for monitoring and predictive maintenance.

- Eco-Friendly Materials - A shift towards sustainable practices in product design and manufacturing.

- Automation - Enhanced automation in processing and material handling to improve efficiency.

- Global Standards - Compliance with international standards for quality and safety will become paramount.

- Advanced Analytics - Use of data analytics to improve decision-making in material management.

Conclusion

In conclusion, crusher screen manufacturers like PolygonMach play an essential role in modern industries by providing reliable and advanced screening solutions. As the demand for efficiency and productivity grows, these manufacturers will continue to innovate, setting trends and standards throughout the sector. By choosing the right manufacturer and investing in high-quality equipment, businesses can significantly enhance their operational capabilities and secure a competitive edge in their respective markets.