Excavator Hydraulic Pumps - The Heart of Heavy Machinery

When it comes to the world of heavy machinery, excavator hydraulic pumps play a pivotal role in ensuring efficiency and productivity. These hydraulic pumps are not just components; they are the very lifeblood of excavators, powering everything from the boom and arm to the bucket. In this comprehensive guide, we will explore the significance of excavator hydraulic pumps, the various types available, their features, applications, and some essential maintenance tips to keep them running smoothly.

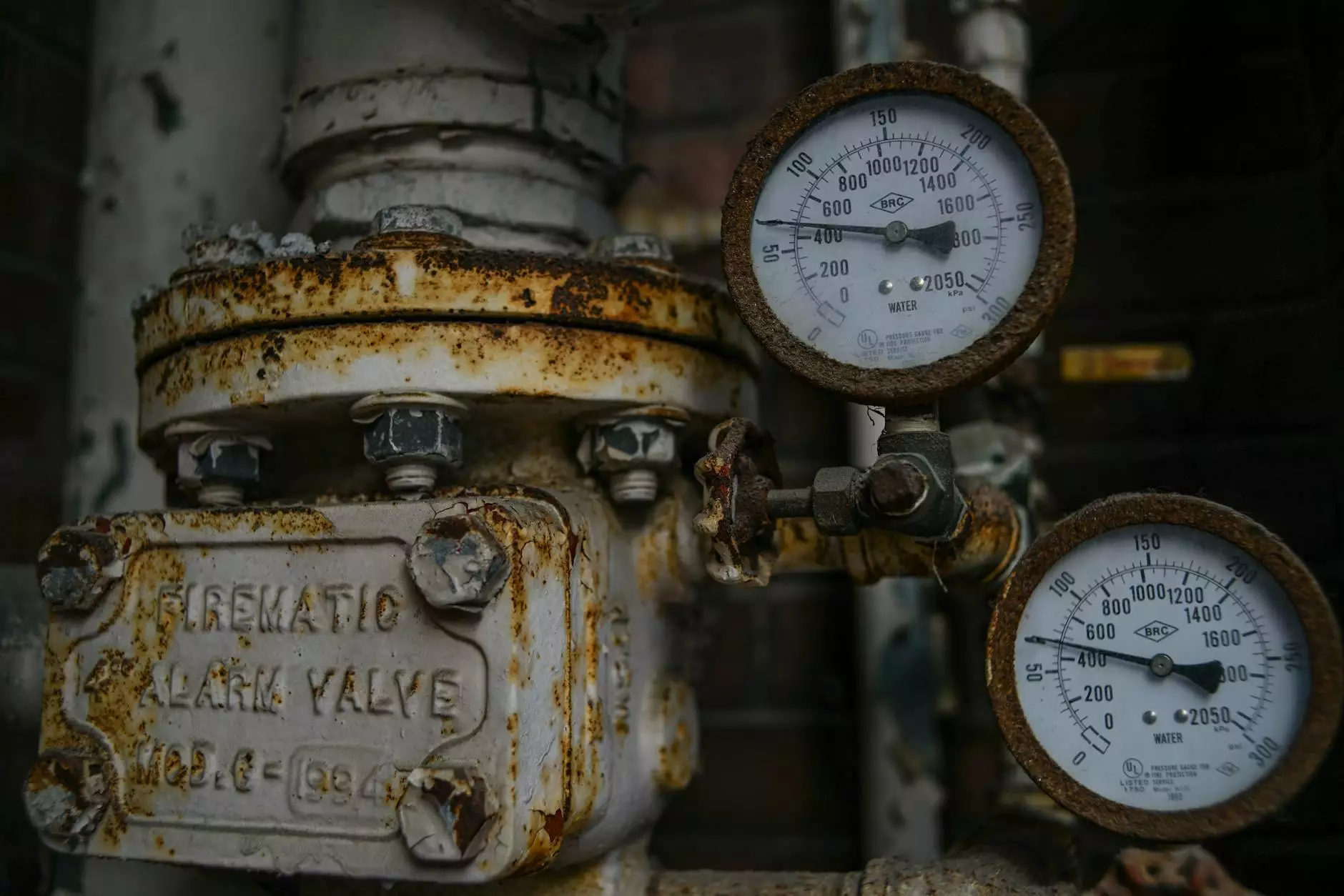

Understanding Hydraulic Pumps in Excavators

A hydraulic pump converts mechanical energy into hydraulic energy through the movement of fluid in a closed system. In excavators, hydraulic pumps serve to provide the necessary pressure to operate the hydraulic cylinders and motors. Without a properly functioning hydraulic pump, an excavator would simply be a static piece of equipment, unable to perform its intended tasks.

Types of Excavator Hydraulic Pumps

When choosing an excavator hydraulic pump, it's essential to understand the different types available. Here are the most common types:

- Gear Pumps: These pumps use gears to pump hydraulic fluid, offering a steady flow and reliability in various conditions.

- Piston Pumps: Known for their high efficiency and ability to generate high pressure; ideal for demanding applications.

- Vane Pumps: They provide smooth flow and are used in applications requiring precise control and performance.

- Hydraulic Screw Pumps: These are efficient in handling different fluid types and offer high durability and low maintenance.

Key Features of Excavator Hydraulic Pumps

Understanding the features of excavator hydraulic pumps can help in selecting the right one for your machinery. Here are some key features to consider:

- Flow Rate: The volume of hydraulic fluid delivered by the pump per time unit, measured in liters per minute (L/min).

- Pressure Rating: Indicates the maximum pressure the pump can handle, crucial for safety and performance.

- Efficiency: How well the pump converts mechanical energy into hydraulic energy. High-efficiency pumps save fuel and reduce wear.

- Durability: Look for pumps made with high-quality materials that can withstand harsh operating conditions.

- Size and Weight: Consider the pump's dimensions and weight, especially if space is a constraint in your excavator setup.

Applications of Excavator Hydraulic Pumps

Excavators are versatile machines used across various industries, including construction, mining, and agriculture. Here are some typical applications utilizing excavator hydraulic pumps:

- Excavation and Digging: Used to dig trenches, foundations, and other earthworks efficiently.

- Material Handling: Powers attachments like buckets and grapples for lifting and moving materials.

- Demolition: Essential for operating hydraulic breakers or munchers to dismantle structures.

- Landscaping: Used for lifting and transporting soil and rocks for landscaping projects.

- Road Construction: Employed in grading and maintaining roads and highways.

Choosing the Right Excavator Hydraulic Pump

Choosing the correct excavator hydraulic pump for your machine is crucial for operational efficiency. Here are several factors to consider when making your selection:

- Compatibility: Ensure the pump matches your excavator model and specifications.

- Performance Requirements: Evaluate the needed flow rate and pressure based on the tasks you intend to perform.

- Brand Reputation: Opt for pumps from reputable manufacturers known for quality and durability, such as those offered by Shop Hydraulic America.

- Cost-Effectiveness: While price is important, consider the long-term value in terms of efficiency and lifespan.

Maintenance Tips for Excavator Hydraulic Pumps

To ensure the longevity and efficiency of your excavator hydraulic pump, regular maintenance is essential. Here are some crucial maintenance tips:

- Regular Inspections: Frequently check for leaks, unusual noises, or any signs of wear and tear.

- Fluid Changes: Change the hydraulic fluid as recommended by the manufacturer to prevent contamination and ensure optimal performance.

- Filter Replacement: Replace hydraulic filters consistently to maintain fluid cleanliness and extend the life of the hydraulic system.

- Check Hoses and Connections: Inspect hoses for cracks or signs of wear and ensure all connections are tight.

- Professional Servicing: Schedule periodic professional inspections and servicing to identify potential issues before they become significant problems.

The Benefits of Quality Excavator Hydraulic Pumps

Investing in high-quality excavator hydraulic pumps brings several benefits, which include:

- Increased Efficiency: Quality pumps enhance the overall efficiency of your excavator, leading to improved performance.

- Lower Operating Costs: High-efficiency hydraulic pumps consume less fuel and require fewer repairs, saving money.

- Reduced Downtime: Reliable pumps minimize the risk of unexpected breakdowns, ensuring your excavator is always ready to work.

- Improved Safety: High-quality pumps reduce the risk of hydraulic failures, which can be dangerous in work environments.

Conclusion

In conclusion, excavator hydraulic pumps are an indispensable component that significantly enhances the functionality of excavators. By understanding the types, features, applications, and maintenance practices associated with these pumps, you can ensure that your excavator operates at peak efficiency. For the best selection of hydraulic pumps and related components, visit Shop Hydraulic America, where quality meets expertise!